Problem of burnt spots on the injected part.

Possible causes may be:.

- Plugged gas leaks.

- Injection speed too high.

- Material temperature too high.

The solutions:

- Clean gas leaks.

- Reduce injection speed.

- Reduction of the temperature of the material.

Problem of spontaneous burrs in the fitting areas.

Possible causes may be:.

- Foreign body in the partition line.

- Over-injection of the part.

- Material temperature too high.

- The machine does not have sufficient clamping force to compensate for the injection pressure.

- Control of mould cooling temperatures.

The solutions:

- Check the fitting areas for foreign matter or plastic residue from previous injection mouldings.

- Verification of partition surfaces to check for possible damage.

- Review of the injection process: speeds, temperatures, load and pressures.

- Regulation of the closing force of the machine.

- Check the cooling of the mould.

Continuous burrs in the adjustment areas.

Possible causes may be:.

- Wear of the adjustment areas.

- Foreign bodies or plastic debris deposited in the seals.

- Machine chucks out of adjustment.

- Misadjusted injection parameters: speeds, load and pressures.

- Material temperature too high.

- The solutions:

The solutions:

- Repair the fasteners and readjust the injection mould.

- Remove foreign bodies or plastic debris in the sealing area.

- Replacement or readjustment of locking plates.

- Review of the injection process: speeds, temperatures, load and pressures.

- Regulation of the closing force of the machine.

- Check the cooling of the mould.

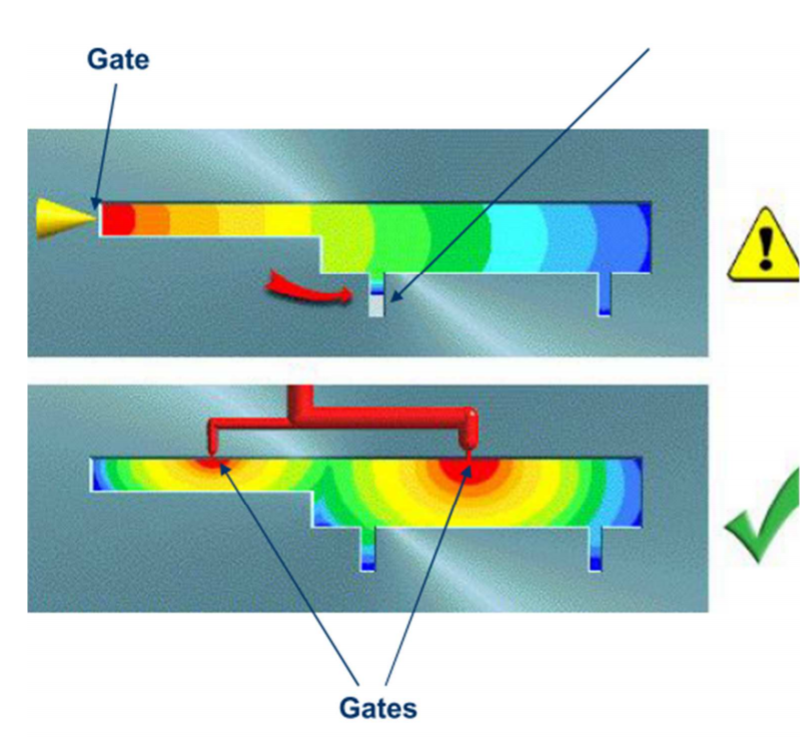

Joining line in an undesired location.

Possible causes may be:.

- Temperature of plastic too low.

- The material entries section is different.

- Clogged injection points.

- Non-uniform heating of the hot chamber.

- Nozzles at different temperatures.

- Inequality of outgassing due to leakage.

- Lack of uniformity in cooling.

The solutions:

- Verification of injection temperatures.

- Check the condition of the injection nozzles.

- Check the operation of the shutters.

- Check the hot block resistors.

- Check for gas leaks.

- Check Mould cooling.