The design and manufacture of molds for plastic injection is a precise engineering that directly impacts the effectiveness, quality, and profitability of plastic component production. The complexity of these tools not only lies in their physical structure but also in the interaction of their components during the injection process.

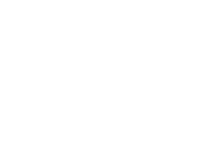

Essential Components of a Plastic Injection Mold

Cavity and Core

Cavity: Precision in cavity machining is vital, as any imperfection can be reflected in the molded piece. Cavities are often designed with integrated cooling systems to facilitate precise thermal control.

Core: In addition to forming the internal geometries of the piece, the core may include complex mechanisms such as movable cores or collapsing systems to create detailed internal features or undercuts.

Mold Structure and Support

Tie Plates and Support

Tie Plate (Slider Plate and Clamp Plate): These plates provide the main support to the mold, ensuring its fixation to the injection machine. The slider plate serves as a base, while the clamp plate is located on top, both held by tie screws.

Male Plate (Ejector Plate) and Female Plate (Cavity Plate): These form the two main halves of the mold, where the plastic piece is formed. The male plate moves to allow mold opening, and the female plate remains fixed.

Shim and Centering Disk: Provide alignment and additional support between mold plates, ensuring precise closure and avoiding deviations during the injection process. Injection and Feeding System

Injection and Feeding System

Sprue, Part Entry, and Cooling Nozzle:

Sprue: Channel through which molten plastic enters from the injection machine into the mold cavities.

Part Entry: Specifically designed to direct the flow of molten material into the mold cavities, ensuring uniform filling.

Cooling Nozzle: Used to control the material temperature in the injection area, preventing premature plastic solidification.

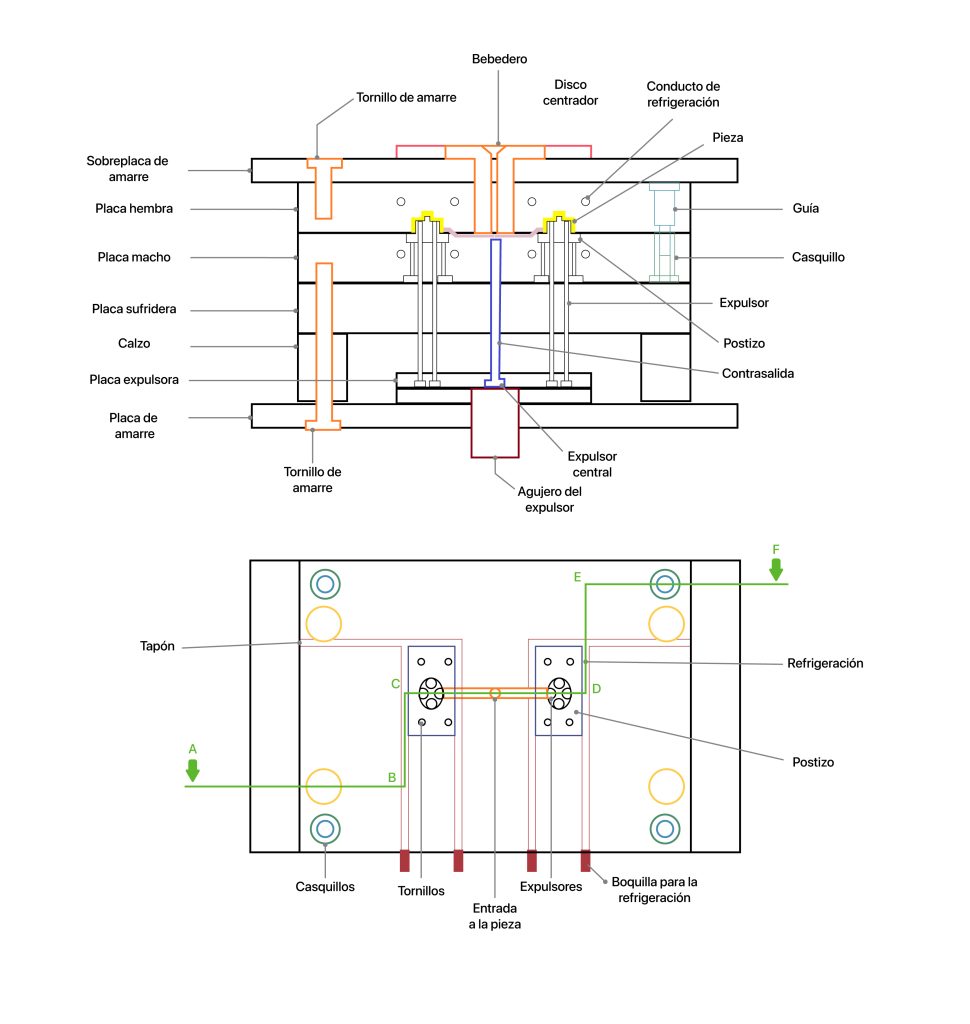

Guiding and Centering System

Guides, Bushings, and Inserts:

Guide and Bushings: These components ensure precise alignment between the male plate and the female plate during mold closure and opening.

Insert: Element used in complex molds to create specific details in the molded piece, facilitating its extraction without damage.

Cooling System

Cooling Channel and Plug

Cooling Channel: Internal channels within the mold through which water or other cooling fluid circulates to control mold temperature, accelerating the cooling of the molded piece.

Plug: Used to close the ends of cooling channels that are not in use or to adjust the coolant flow.

Ejection System

Ejector Plate, Ejector Pins (Ejectors), Ejector Pin Hole, and Central Ejector

Ejector Plate: Supports ejection mechanisms that remove the molded piece from the mold.

Ejector Pins (Ejectors) and Central Ejector: Pins or bars that push the molded piece out of the mold cavity once it has solidified.

Ejector Pin Hole: Holes in the ejector plate through which ejectors extend to contact and eject the molded piece.

Other Components

Undercut and Screws

Undercut: Refers to mechanisms or configurations that allow secondary movements within the mold, such as sliders or lifters, to create complex features in molded pieces.

Screws: Used to firmly fix all mold parts, ensuring their stability and strength during the injection process.

Cooling System

Cooling systems are now designed using computer simulations with various software to achieve uniform temperature distribution throughout the mold. This is crucial to minimize cycle time while maintaining part quality.

Inserts and Adjustment Plates: Flexibility and Control

Inserts: Their use allows mold adaptability to produce variants of a piece without incurring the costs of manufacturing a new mold. Inserts can be easily exchanged to adjust specific features of the molded piece.

Adjustment Plates: These components are essential for fine-tuning the mold, allowing precise control of injection and ejection, especially in molds with complex geometries or tight tolerances.

Other news of interest